Integration of a New Evaporator

Discover how Alps Group supported Nestlé in the integration of a second evaporator to increase powdered milk production for Nescafé Dolce Gusto pods in Challerange.

Context

The Nestlé Challerange site, originally dedicated to Maggi products, became an excellence center for milk powders in 2009, supplying 74 countries with Nescafé Dolce Gusto pods. In 2014, a €12 million investment funded the addition of a second evaporator to meet growing demand. Each year, the factory processes 80 million liters of milk sourced from over 200 local producers.

Project Objective: Speedy Project - Integration of a New Evaporator

Optimize production by integrating an additional evaporator that meets Nestlé standards, maximizing the efficiency of powdered milk production.

Implementation

Nestlé turned to Alps Group for its expertise in evaporator automation. Alps Group’s teams trained Challerange engineers on the Nestlé Engineering Automation Toolbox 6.0, making it easier to use tools and adhere to Nestlé’s internal standards.

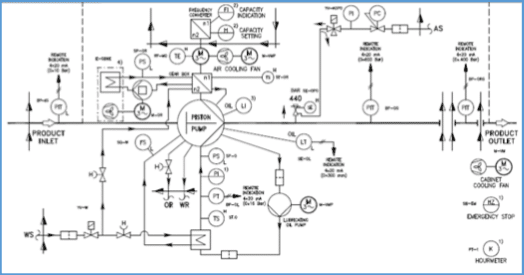

An evaporator software specialist from Alps Group contributed technical expertise to finalize the flowsheet and optimize the project.

The intervention included:

- Migration of existing software to meet Nestlé standards

- Development and commissioning of the evaporator software

- Project management to ensure smooth integration