ATEX

Explosive Atmosphere Zones (ATEX) present potential risks that can be managed through appropriate measures and the installation of specific equipment. If you suspect the presence of such zones on your industrial site, our team can help you precisely identify the areas to be secured and recommend the necessary measures to ensure compliance.

ATEX Classification Area

- Collection of technical data

- Facility audit and process analysis

- Study and classification of ATEX zones in compliance with the EN60079-10 standard and SUVA guide 215

Compliance Audit

- Identification and marking of equipment

- Verification of equipment compliance within ATEX zones

- Inspection of the protection modes of equipment (safety alterations, wear, lack of maintenance, etc.)

- Risk analysis for non-compliant mechanical equipment installed before 2003, based on the TR BCI 156 and DTU 83 guidelines

DRPCE (Explosion Protection Document)

- Assistance to the site manager in preparing the Explosion Protection Document (DRPCE) in compliance with European Directive 99/92/CE and SUVA guide 2153

- Risk analysis of work zones prone to explosion, based on ATEX zoning and adequacy audit

- Determination of organizational measures to implement in ATEX zones

- Drafting and compilation of the DRPCE.

They put their trust in us

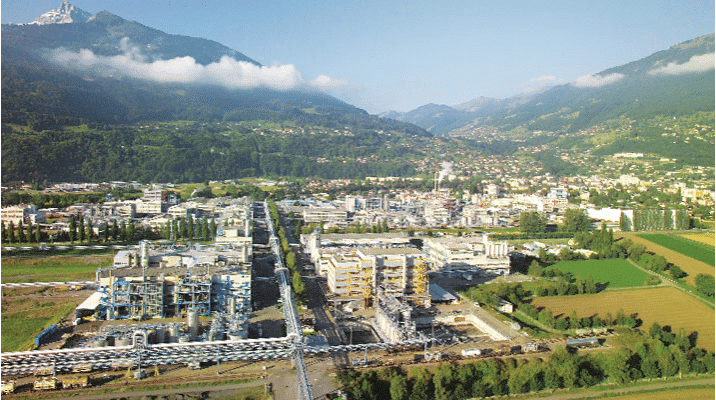

This was the first time Alps Safety produced ATEX cabinets for Syngenta. Everything went smoothly, with nothing negative to report! Alps Safety managed the interactions with the electrical installation teams very well. We are satisfied with the quality of work delivered and have experienced no issues for over three years. I would also highlight the excellent impression left by their Vouvry facilities, a modern workshop with up-to-date equipment aligned with high-quality standards.

Syngenta

Your problem

has a solution

Ask iAlps to get immediate answers.