Machine Park Safety Assessment

Discover how Alps Group conducted a comprehensive risk assessment of 73 machines used in Sanaro SA's automated production lines.

Context

Founded in 1943, SANARO SA specializes in the production of dietary supplements and sweeteners, exported to over 60 countries. Since its integration into the Klosterfrau Healthcare Group in 1971, it has produced well-known brands like Assugrin, Hermesetas, and Taxofit. With automated production lines and FSSC20000 certification, SANARO SA is committed to maintaining the highest standards of quality and safety.

Identify potential risks across a fleet of 73 machines

Classify them by risk level, and prioritize safety actions for industrial compliance.

Achievements

Alps Safety, the industrial safety division of Alps Group, applied a rigorous methodology to assess the risks associated with each machine and production line.

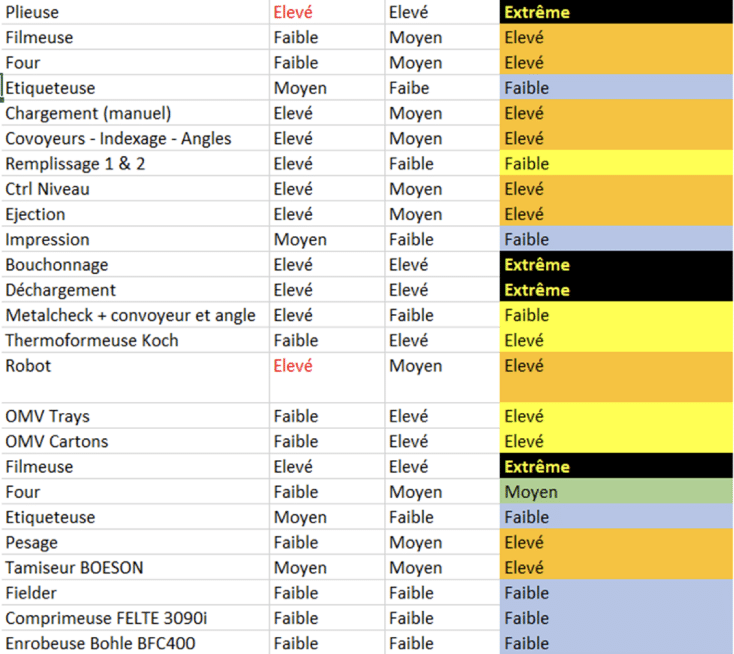

The 73 machines were classified into four risk levels: low, medium, high, or extreme.

This classification allowed for the creation of a precise action plan, outlining corrective measures and an estimated budget for each action.

As a result, the company was able to prioritize necessary actions to ensure the safety of its operations, protect employees, and comply with safety standards.