Retrofit of an Automated Storage System

Discover how Alps Group modernized Saint-Gobain ISOVER’s automated storage system, enhancing safety and efficiency while minimizing downtime.

Context

Saint-Gobain ISOVER, Switzerland’s leading glass wool manufacturer based in Lucens, invested in an automated warehouse in the 1980s to store up to 4,000 pallets of finished products. However, cybersecurity concerns made it necessary to overhaul the warehouse management system, requiring modernization to meet current safety standards and integrate new PLCs.

Renovation of the Automated Storage System

Upgrading the warehouse management application, modernizing equipment, and ensuring seamless integration with new PLCs while adhering to strict timelines.

Achievements

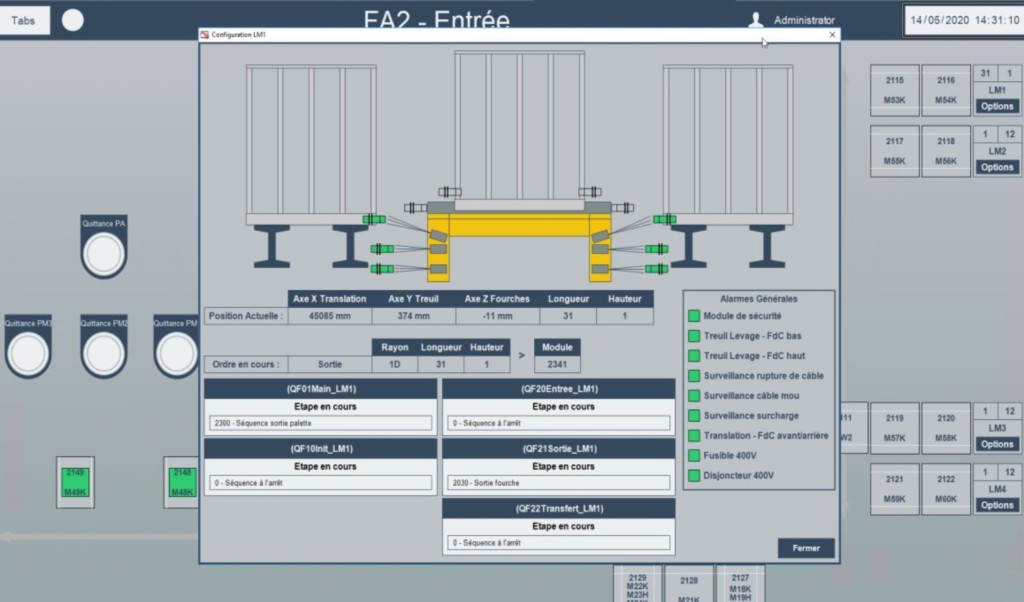

Alps Group carried out a full retrofit of the proprietary warehouse management application, handling nearly 100 motors and 1,000 I/O points. The project included:

- Electrical Panel Upgrade: Designed and built new electrical panels to meet updated safety standards, integrating six new Siemens PLCs

- Communication Adaptation: Ensured compatibility between new PLCs and legacy motion control systems

- New Supervisory System: Developed a new supervision interface on Archestra System Platform, integrating SAP via middleware

- Rapid Deployment: Restarted operations in under five weeks, with PLC and supervision development completed in less than four months