Retrofit of the Cavemil 600

Discover how Alps Group carried out the complete retrofit of the Cavemil 600 machine, enabling the molding and packaging of filled chocolate bars.

Context

Founded in 1819 by François-Louis Cailler, the Cailler chocolate factory is the first modern chocolate manufacturing facility in Switzerland. After merging with Nestlé in 1929, Cailler became an iconic brand. Today, the Broc site employs over 400 people and supplies chocolate products worldwide. However, the Cavemil 600, essential for molding and packaging, required modernization after more than 30 years of operation.

Cavemil 600 Retrofit

The goal was to improve the reliability of the Cavemil 600’s control system, ensuring compliance with Nestlé’s standards and facilitating an efficient transition of production volumes to a new line.

Achievements

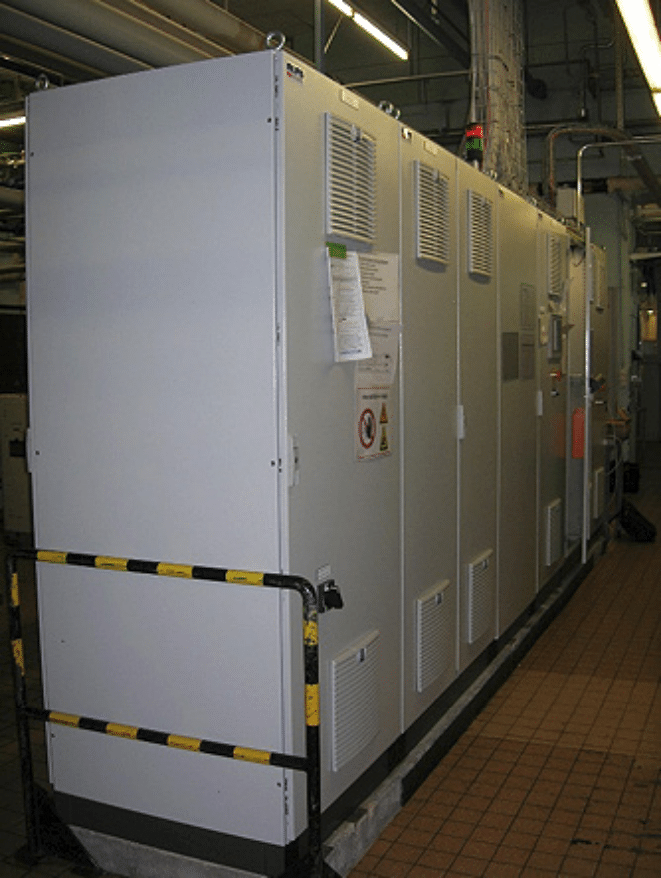

Alps Group carried out the retrofit of the Cavemil 600 by providing a solution that met Nestlé’s standards, including a zero-access system and an Allen Bradley technology platform.

The key steps undertaken by Alps Group included:

- Designing new systems to optimize the operation of the Cavemil 600

- Dismantling and recycling the old control and power cabinets

- Designing and installing new, customized control panels

- Conducting acceptance tests to ensure proper functionality before commissioning

- Installing and commissioning the machine on-site, ensuring an optimal startup

- Fully programming the new components for seamless integration

Thanks to this intervention, Nestlé Chocolats Cailler was able to maintain its production levels while adhering to the initial budget and deadlines, reinforcing its position in the global chocolate market.