Multivac machine retrofit

Upgrade of a Multivac machine and creating a roadmap for the future.

Context

Ferring is a biopharmaceutical company focused on developing innovative treatments that make a real difference in the lives of individuals worldwide.

At its production site in St-Prex, Switzerland, Ferring faced an issue with the MULTIVAC machine, a semi-manual thermoformer that converts PET rolls into molded trays, used for packaging syringes, vials, or products.

The complexity of the machine, dating back to 1993, required the intervention of the European manufacturer, which would have led to long delays and problematic production stoppages. Ferring turned to Alps Services to help and carry out a complete machine commissioning.

Troubleshooting and bringing the Multivac machine up to electrical, mechanical, and IT standards.

Integration of various electrical design services.

Review and standardization of electronic cards and electrical panel, update of spare parts, and upgrade of maintenance and backup systems.

Achievements

The complete commissioning and troubleshooting, including:

- Project management

- Electrical study, including inventory of all electrical cabinets and components (input/output cards, frequency converters, spare parts)

- Assessment of the operating status of all automation systems (memories, cycle times, etc.)

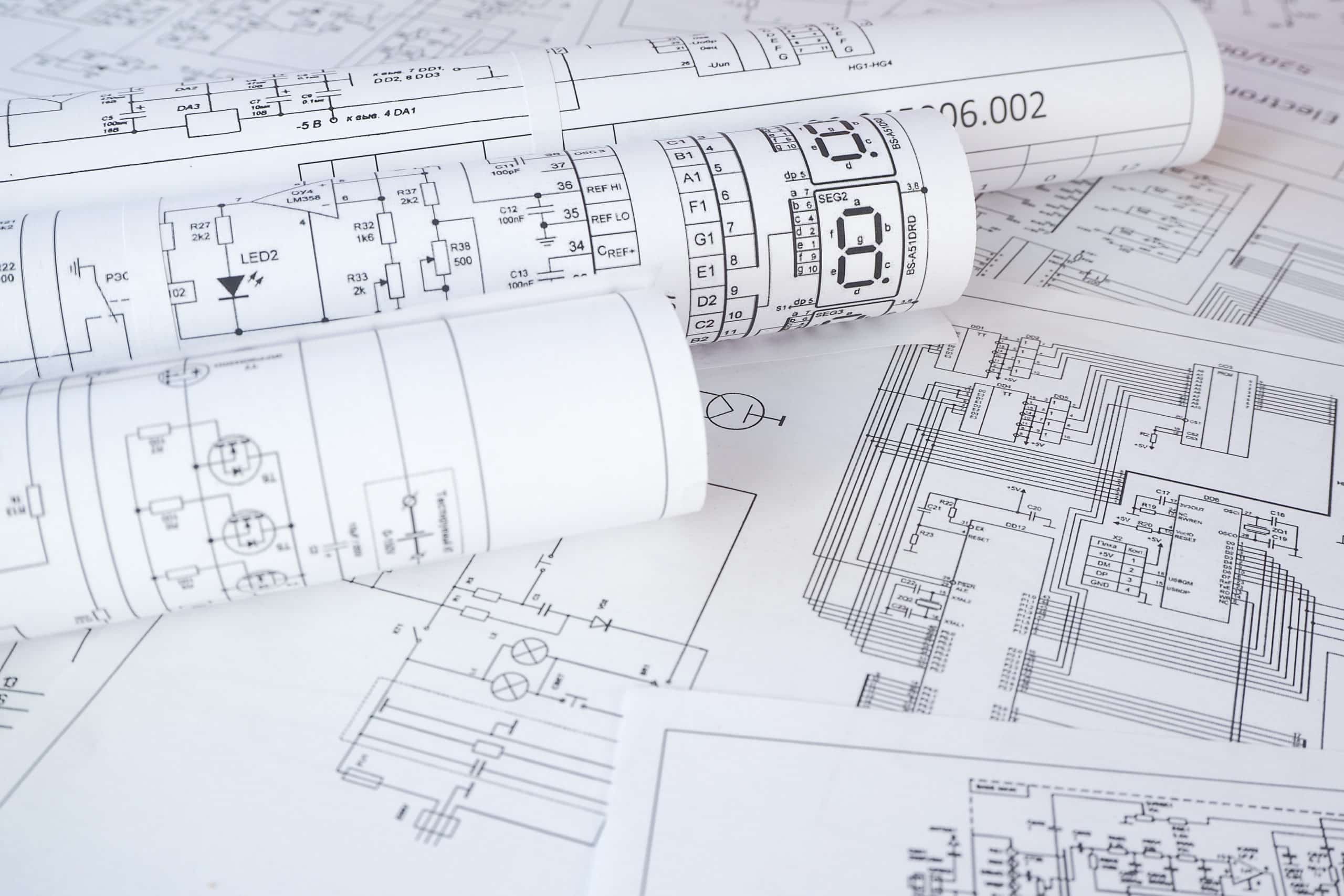

- Complete schematics

- PLC and HMI programming

- Batch report definitions

- Creation of access rights and an audit trail in line with the domain controller, compliant with 21 CFR part 11

Following an audit of production operators, line managers, and maintenance personnel, the following documentation was established:

- A table of product references used, highlighting deficiencies in stock levels and obsolescence of certain references for each cabinet;

- A skills matrix consolidating the capabilities of automation personnel to intervene on the installations;

- Proposals for improvements with an external and neutral perspective;

- A comprehensive, multi-criteria roadmap.

of the Alps Services team. At Alps Group they don't let problems drag on; support is fast. The partnership continues with, for example, the modification of the machine to add a two-hand control.